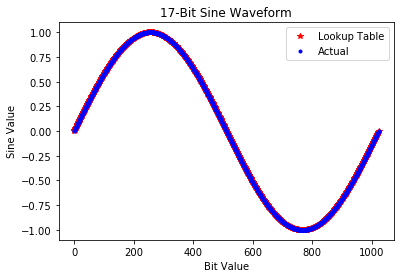

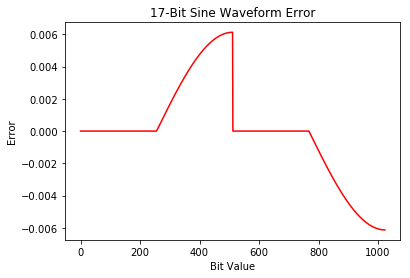

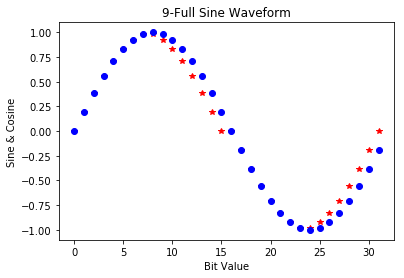

When building a sine lookup table, you can use the symmetry of the sine wave to save lookup table resources. This seemed like a straightforward task but actually had an interesting problem. The sine wave below looks fine, but when compared to the actual waveform a period function appeared in the data.

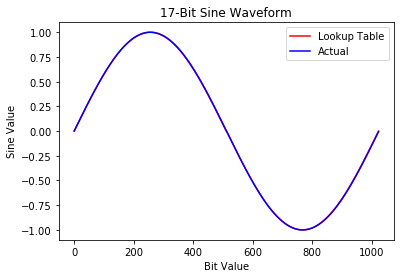

The crux ended up being phase quantization. This is shown clearly when the table is reduced to an 8-deep table:

In the initial calculation the sine wave lookup table was based on the equation:

lookup_table(x) = sin((pi/2)*(x/lookup_table_size))

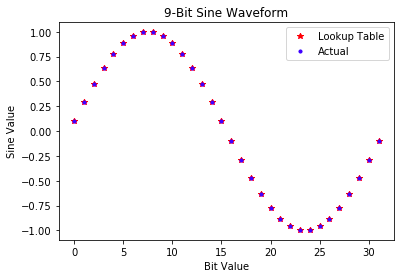

Which resulted in the plots above. While this error probably doesn’t matter much for my application, I was a bit confused by it. I hunted around a bit and found this website which went into detail about the problem and identified a solution which was a half phase slip using the equation

lookup_table(x) = sin((pi/2)((2*x+1)/(lookup_table_size*2)))

This results in a sine wave that’s been shifted, but is otherwise dead on the calculated version!

Which holds as the quarter wave table is expanded to its full scale, 256×16